Week 10

our first activity was to complete the laser cutting quiz in class and to do SOP once completed the quiz.. we were sharing answers to help one another to get 80% n above..

once quiz completed, we started our proper lesson about laser cutting.. there are two types of cutter made readily for us - epilog n universal

we're taught on the components and the working principles of the laser cutter, it requires compressor and exhaust to work

we also have to understand the importance of choosing the correct materials for laser cutting as there are strengths and weaknesses for different type of laser cutter we are going to use.. one type of material we should NEVER use is any material containing chlorine because chlorine is highly reactive and corrosive, it will cause damage to the cutter

some suitable materials are listed below vv

- wood

- acrylic

- cardboard

- paper

workflow of phone stand

i was inspired by a deep blue acrylic bookend i saw online. the clear, transparent material of the bookend made it look like a glass, and i loved the simple, geometric design as it will never go out of style !! i decided to use this design for my phone stand, with additional customisations to make it more unique, by adding a hook and instead of adding an image for engraving, i added my name to signify mine :D

the dimensions of my iPhone 13 pro max is 16cm by 7.8cm by 0.76cm

First,

I drew a 25mm by 25mm square on fusion360. Next, I exported the file into

CorelDraw for laser cutting. Once the square has been laser cut out, I tapped

the square on the machine before removing them to ensure all sides have been

fully cut off. Next, I measured the length of the square with a vernier caliper

and it shows me roughly about 24.6mm. I used the expected length minus the

actual length which is 25mm – 24.6mm which gave me 0.4mm (kerf) and I use this

to edit on the length from fusion360 before the cutting of my phone stand.

Kerf:

Design width – actual width = 25mm – 24.6mm = 0.4mm

I did

not manage to calculate the compensation as it is not necessary for my phone

stand, so what I did is I use the dimensions of the hole (10mm length by 3mm

width) which is 3mm width to minus away 0.4mm of kerf.

Design

width: 3mm – 0.4mm = 2.6mm

On my

sketch, I made modifications to the parameters that I had prepared initially. I

adjusted accordingly and fusion360 will updates it automatically which is an

advantage for me as it saves me much time because I do not need to adjust in

manually.

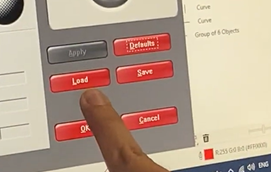

Workflow for preparing dxf file

short video of laser cutter in action

short video of press-fit quality

final assembled product

my "hero shot"

Learning reflection:

I have learnt so much from this laser cutting assessment from

the difference type of laser cutter available in school, to the final production

of my phone stand. I learnt about the basics of laser cutting and the different

types of materials that can be used in the laser cutter and learned how to use

CorelDraw to create laser cut files. I was also introduced to the concept of

kerf, which is the width of the cut made by the laser cutter. This is important

to consider when designing laser cut parts, especially when we are dealing with

press-fits. I was able to successfully design, and laser cut a phone stand

using the knowledge I learnt. I am proud of the final product, and I am

confident that I can use these skills to create other laser cut projects in the

future. One of the things I found most confusing about laser cutting was

calculating kerf. However, I was able to overcome this challenge by following

the examples given to us in the Brightspace, where they teach us how to find

kerf before proceeding to cut. This allowed me to make the necessary

adjustments to my design and I was able to laser cut the phone stand without

problems arising. I realised the importance of making sure I calculate kerf

before proceeding to laser cut my phone stand. Kerf is important to be

considered when designing laser cut parts due to press fit. By taking kerf into

account, I can ensure that my phone stand parts can fit together tightly and

securely. I have also found perks being a pro user in fusion360. Initially when

I started to create my sketch for my phone stand, I had to manually change the

dimensions to create a perfect one. Now, I can make all my adjustments with the

help of fusion360 parametric accurately and time efficiently. This will definitely

help me with any upcoming laser cutting projects to save time and make it more precise. (~333 words)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

No comments:

Post a Comment